Forging Simulation

Get in touch

Call us now on

+44 (0)1902 366 440

Email your enquiry to sales@whtildesley.com

A full list of contacts can be found on the contact page

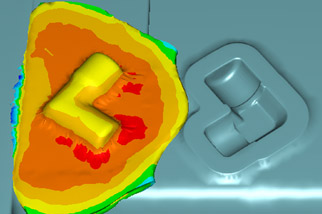

Simulation software ensures we get it right the first time, every time.

We have a disciplined approach to forging and die design. Every job is simulated before dies are cut to ensure that material usage and process are optimised. This enables us to evaluate the overall process before any major cost is incurred.

Every new component we produce is generated in 3D form using the latest Solidworks and Creo packages. These models, combined with simulation software, enable the development of part geometry and test forging die / tooling design. This helps us to eliminate potential forging defects such as cracking or under-fill.

Software Solutions

W.H.Tildesley uses the latest in forging simulation software, Quantor Form and Transvalor. This is combined with the latest industry-standard CAD and CAM software. This includes 3 seats of CREO and Solidworks.

|

|

|

-

Drop Forging

Drop forged components from 25 Grams up to 100kg net weight We are the closed die drop forging experts and one of the leading drop-forged component produce...

Read More -

Die Manufacture

Our forging dies and tooling are produced in-house, guaranteeing quality and improved lead times Our fully integrated CAD/CAM package links product and die...

Read More -

Component Design

We provide full engineering support at the product design stage of the forging process Our skilled team of engineers and experienced technicians are here to ass...

Read More

Use of industry leading forging simulation software

Ensuring the correct component is produced