What is Drop Forging?

Get in touch

Call us now on

+44 (0)1902 366 440

Email your enquiry to sales@whtildesley.com

A full list of contacts can be found on the contact page

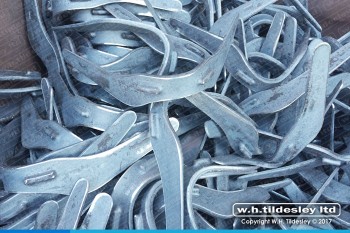

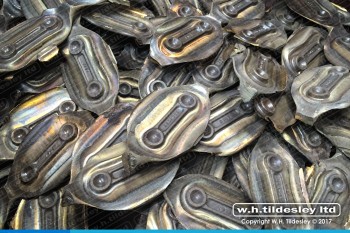

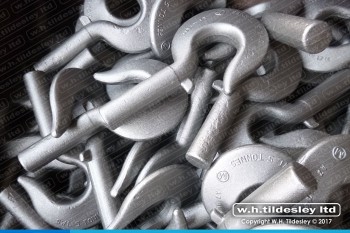

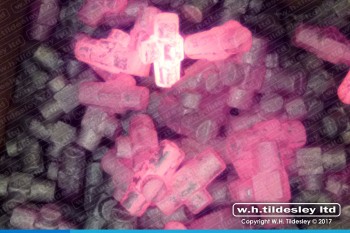

Drop forging is a process that uses a pair of impression dies and a heavy hammer to form and compress metal bars or billets into complex shapes. The impression or die cavity is the desired shape of the final forging.

The equipment used in the drop forging process is known as a power or drop hammer.

Drop hammers are typically mechanical where the weight and upper die are lifted by a belt or chain and dropped. Power hammers are powered by air or hydraulics and are typically used for heavier production.

The lower half of the forging die is fixed in position on the anvil and the upper is fixed onto the ram that moves up and down.

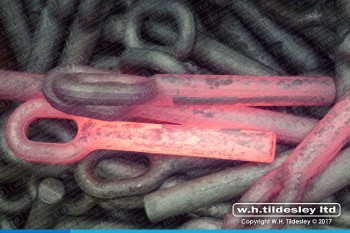

Material is heated to the required temperature and then placed into the lower forging die in its plain or preformed condition. The material is then hammered until it completely fills the die cavity. The process can also be called impression die forging.

A preform is an open die forging process that manipulates the material into a rough shape to assist with grain flow structure and forming in the impression die.

Forging dies are designed to allow excess material to be pushed outside of the impression, this is commonly known as flash material which is later removed in a trimming operation. A draft angle is also added to the impression to allow the material to release from the forging die after forming.

W.H.Tildesley forge in both ferrous and non-ferrous materials including carbon steel, stainless steel, aluminium (aluminum), nickel alloys, bronzes, and titanium. We run 10 forging cells in one of the most modern drop forging facilities in the UK.

-

Drop Forging

Drop forged components from 25 Grams up to 100kg net weight We are the closed die drop forging experts and one of the leading drop-forged component produce...

Read More -

Open Die Forging

Open die forgings are produced by our skilled operators, ensuring the dimensional and consistent accuracy of the product from start to finish. The open die forg...

Read More -

Machining

Extensive in-house machining capability for proof or finish machined forgings Our in-house machining gives us the capability to offer proof or finished machined...

Read More -

Component Design

We provide full engineering support at the product design stage of the forging process Our skilled team of engineers and experienced technicians are here to ass...

Read More -

Forging Simulation

Simulation software ensures we get it right the first time, every time. We have a disciplined approach to forging and die design. Every job is simulated before ...

Read More -

Die Manufacture

Our forging dies and tooling are produced in-house, guaranteeing quality and improved lead times Our fully integrated CAD/CAM package links product and die...

Read More